Sculpture

A concentration in sculpture provides a creative atmosphere in which the varied histories, conceptions, and manifestations of sculpture can be actively realized. Students, along with their faculty and staff, form a dynamic learning environment where a diverse range of backgrounds, subjects, and goals are explored, discussed, and given shape.

While each instructor offers students a different perspective on sculpture, a shared vision exists and is focused on the development of a student's ability to intelligently express themselves while contributing to culture through sculpture making and as an engaged and thoughtful citizen.

Career opportunities

- Professor/instructor

- Independent artist

- Moldmaker

- Modelmaker

- Digital sculptor

- 3D artist

- Stone cutter

- Materials technician

- Fabricator

- Woodworker

- Production artist

- Independent artist

- Foundry technician

- Mortuary sculptor

- Sculpture restorer

Facilities

Sculpture Studio

- Main room approximately 2,449 square feet 79' X 31' with 12' from floor to light

- Figure sculpture room approximately 1,209 square feet 39' X 31' with 12' from floor to light

- 208 volts max 60 amps

- Compressed air 90 psi

Foundry

- Approximately 4,124 square feet 73 X 56 1/2"" with 11"" from floor to bottom truss

- Fenced off outdoor area approximately 810 square feet 44"" 7"" X 18""3""

- 208 volts three phase max 30 amps

- 208 volts single phase max 80 amps

- Compressed air, 90 ps

- Dual foundry furnaces capable of casting 200lbs of bronze and 100lbs aluminum, each

- Iron cupola with 200lbs pouring capacity

- 1 ton overhead shop crane over main casting area

- 7 ½ cubic foot stationary burnout kiln

- 8 cubic foot portable burn out kiln

- Muller capable of mixing 250lbs of sand

- Sodium silicate sand casting capabilities

- Ceramic shell casting capabilities

- 12 Full sets of leather safety gear for casting

- 2 ton Portable engine hoist

- Yale Forklift 4000lb max capacity

- Glove-box sandblaster with filter

- Portable patina station

- Compressed air and conveniently located hose reels

- Outdoor coal forge

Woodshop

- Powermatic model 90 lathe

- Jet oscillating spindle sander with filter

- 6"X48" belt sander with 10" wheel and filter

- 14" Delta band-saw

- 18" Dremel scroll saw

- 8 ½ Hitachi sliding compound miter saw

- 20" Kalamazoo wood sander

- 1/3 hp delta adjustable drill press

- Large glove-box sandblaster with filter

- Large Rockwell band-saw

- Compressed air and conveniently located hose reels

Wax and Moldmaking

- Multi burner gas stove

- Wax steamer

- 2 Riteheat 18 quart wax cookers for foundry wax and bees wax

- ½ hp Robinair vacuum pump with desiccator

Stone

- Stone working stations that include sand bags and vises

- Stone chisels both hand and pneumatic

- Various burrs and bits for stone working

- Various masonry bits

- Drift and wedge sets

- Hand stone saws

Ceramic Shell Investment

- 3 hp Duramix continuous duty mixer on timer with adjustable tank set up

- 20 gal slurry tank with optional 60 gal tank

- Fluidized stucco bed

- A and B stucco stations

Glass

- 19 cubic foot Glass Annealing kiln

- 8"" tile cutter

Welding/Fabricating

- Syncrowave 350 tig welder with external cooling, foot pedal and arc capabilities

- Millermatic 175 mig welder

- Lincoln Procut 20 plasma cutter

- Miller thunderbolt XL arc welder

- 1.5 KVA miller stationary spot welder

- 2 Oxygen-acetylene welding torch setups with and cutting capabilities

- Jet 40" 20 gauge combination shear break roll

- ¾ hp 15" Wilton drill press

- 14" Milwaukee abrasive cutoff saw

- 20" Kalamazoo metal sander

- ½ hp Baldor pedestal grinder

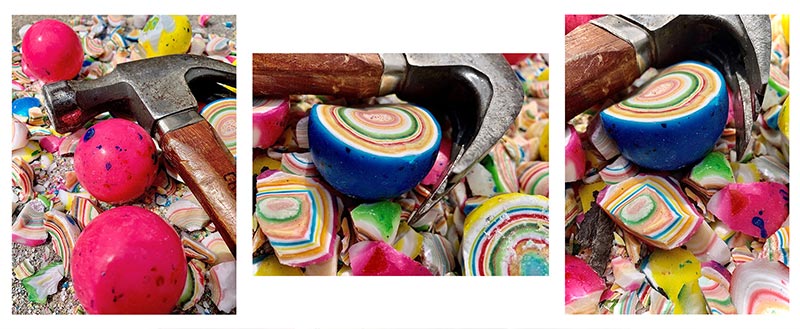

Student work gallery

Area coordinator

Eric Troffkin (MFA)

Associate Professor

eg2919@wayne.edu